Product Category

CONTACT US

Tel :

+86 18390885700E-mail :

sales@xiangjiasteel.com

Application

High-frequency straight seam electric-resistance welded steel pipe(erw steel pipe) is hot-rolled coil after forming machine, the use of high-frequency current skin effect and proximity effects, the tube edge heating and melting, squeeze roller under pressure welding to achieve production.

High-frequency resistance welding steel pipe, welding pipe and ordinary welding process is not the same, the weld is made of the base metal melt from the body, the mechanical strength is better than the general pipe. Smooth appearance, high precision, low cost weld high and small, favorable 3PE anti-corrosion coating. There are significant differences in the welding methods between high frequency welded pipe and submerged arc welded pipe. As the welding is done instantly at high speed, the difficulty of ensuring the quality of welding is much higher than that of submerged arc welding.

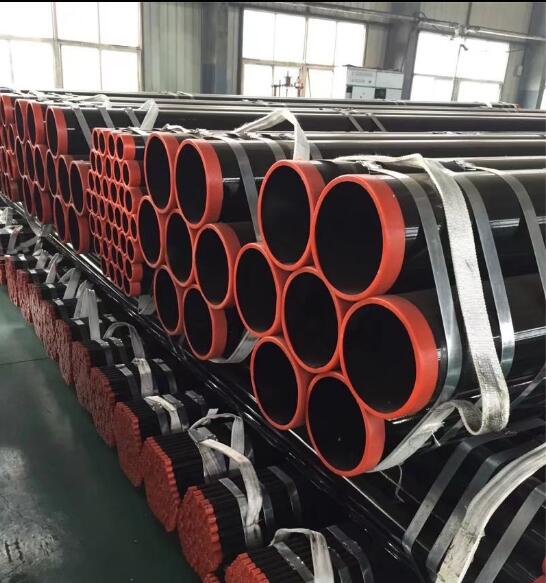

ERW pipes are used in various engineering purposes, fencing, scaffolding, line pipes etc. ERW pipes are available in various qualities, wall thicknesses, and diameters of the finished pipes.

Specification

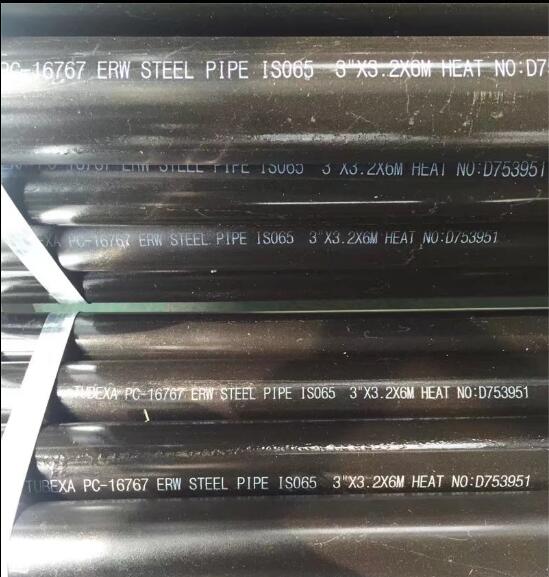

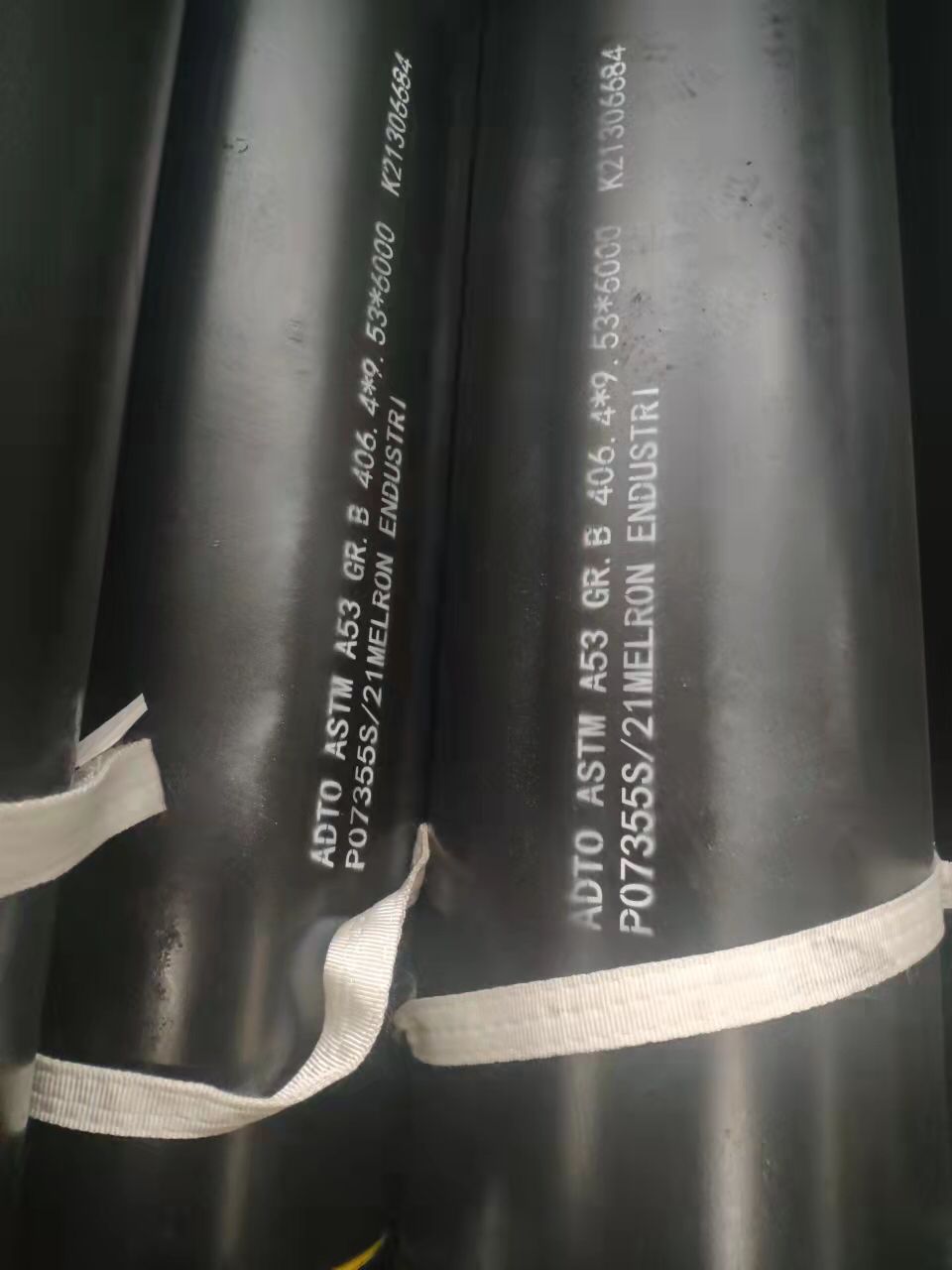

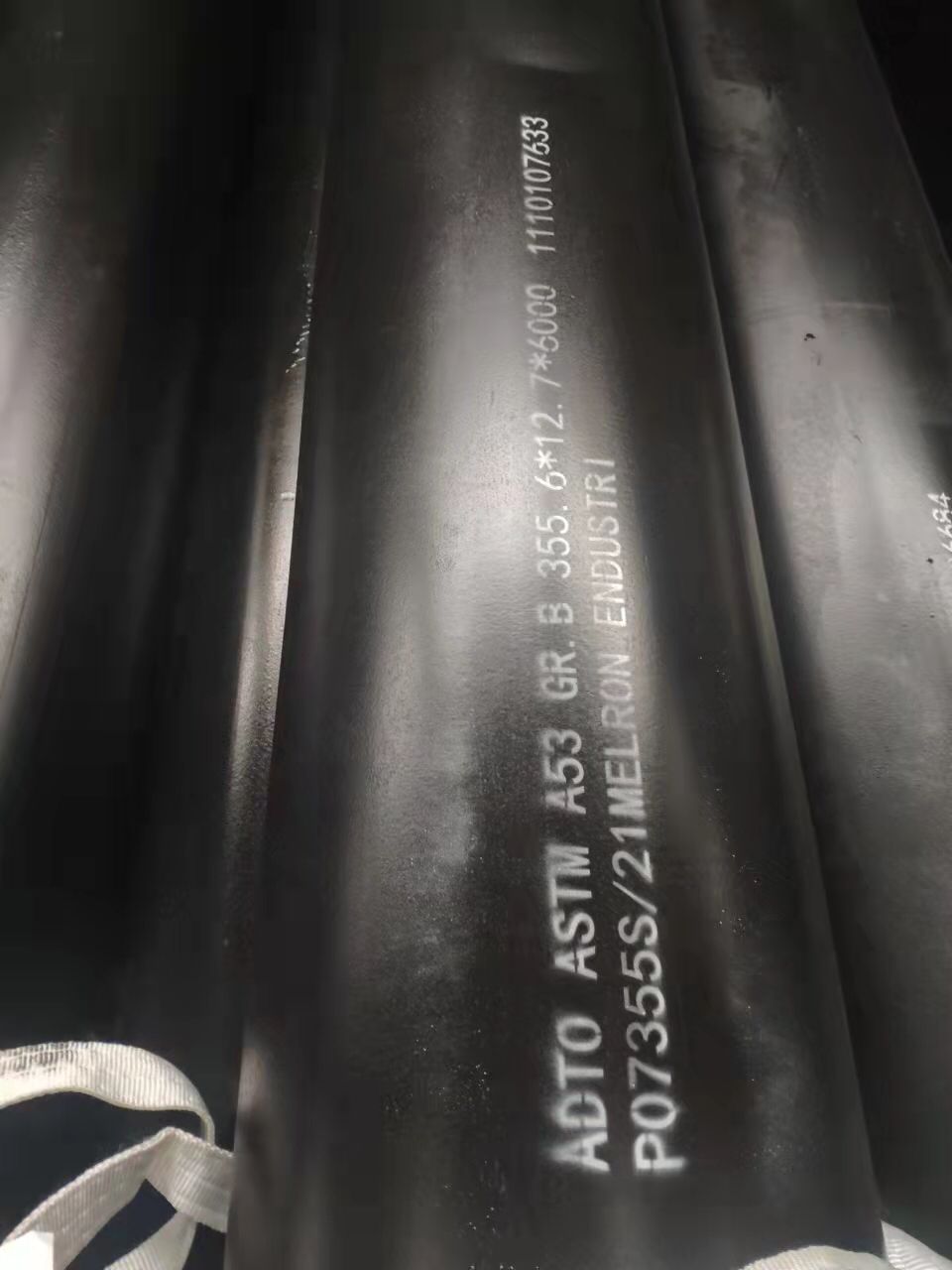

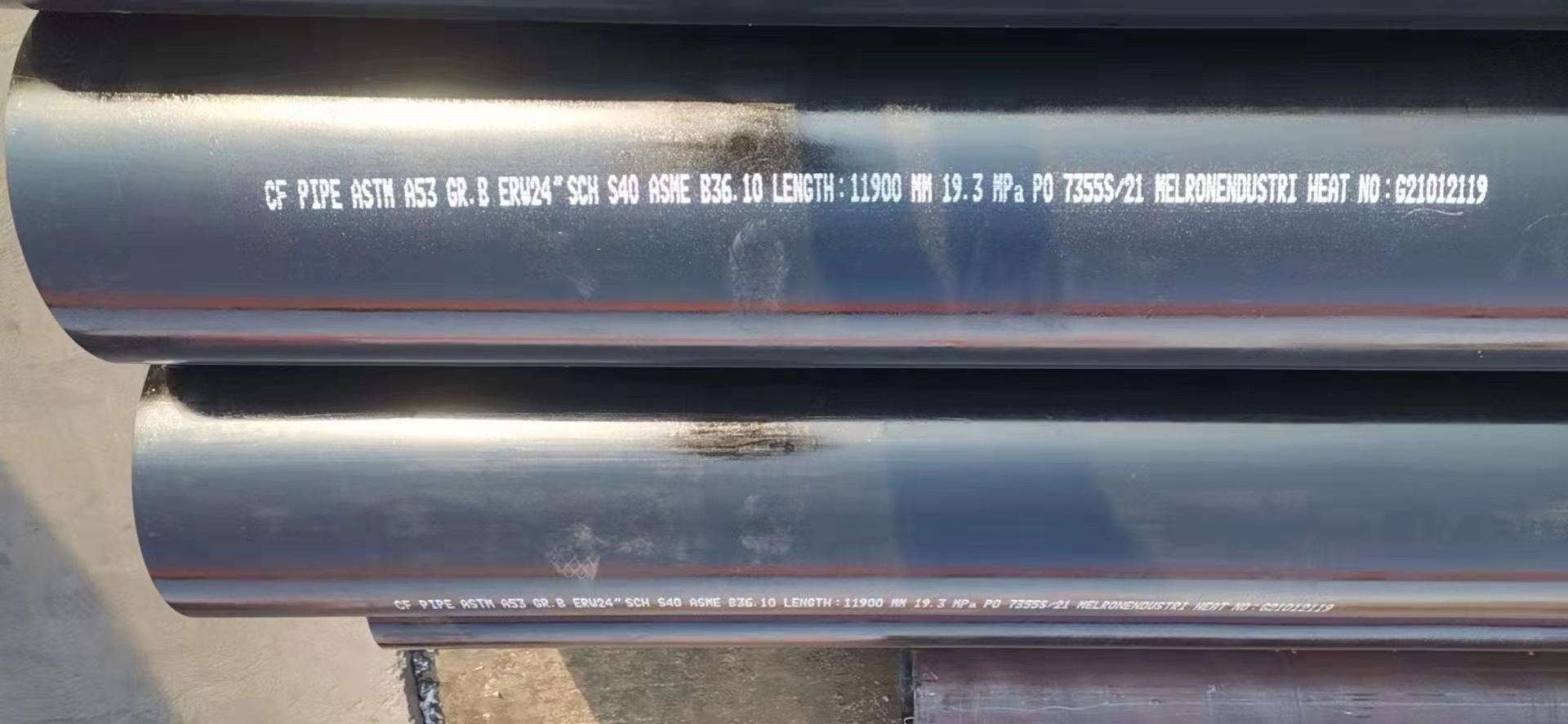

ERW (Electric Resistance Welded ) Steel Pipe, ERW Casing, ERW Carbon Steel Pipe, MS ERW Pipe, GI ERW Pipe

Out diameter: 1/2" -24"

Weight Length: 1.0-20mm

Thickness: sch5, sch10, sch40, sch80, st, xs (according to the ASME B36.10M)

Standard:

For ERW Pipe

ASTM A53 B, A106, ASTM A178, ASTM A252

API 5L X42/46/52/56/60/70

ASTM A500, ASTM A513

EN 10204/10217 S235JR,S275JR, S355,S355JR,S355J2H

For ERF Pipe

Carbon Steel EFW pipe: ASTM A671,ASTM A672

Alloy Steel EFW pipe: ASTM A691

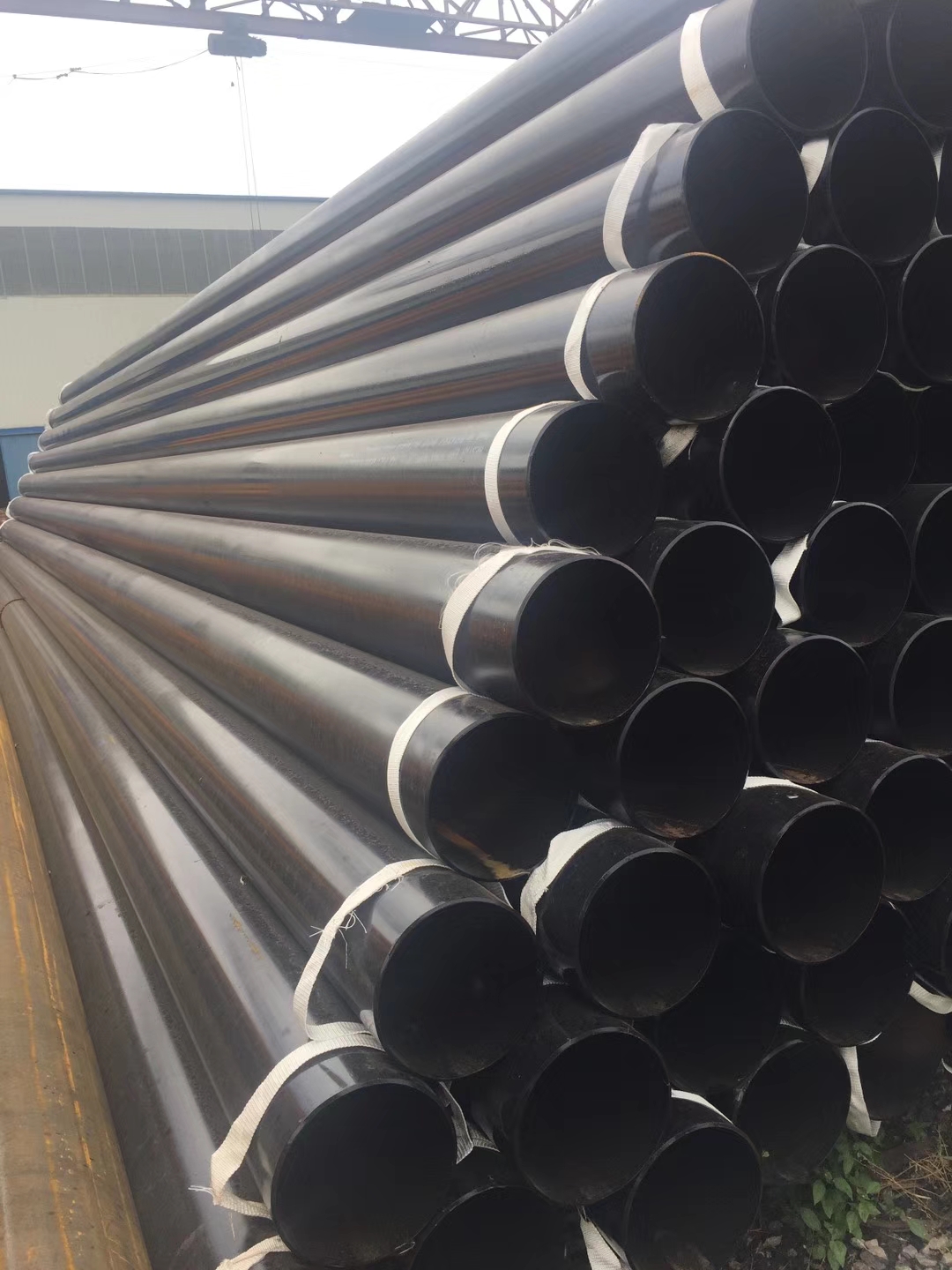

Coating

3PE Coating 3PP Coating FBE Coating Epoxy Coating Special Painting

Uses:

For ERW Line Pipe

For ERW Casing

For ERW Structure Tube

For High pressure and high temperature

Tolerance of Outside Diameter

| Standard | Out Diameter | Tolerance of Pipe End | Tolerance of Pipe Body |

|---|---|---|---|

| API 5L | 219.1~273.1 | +1.6mm, -0.4mm | ±0.75% |

| 274.0~320 | +2.4mm, -0.8mm | ±0.75% | |

| 323.9~457 | +2.4mm, -0.8mm | ±0.75% | |

| 508 | +2.4mm, -0.8mm | ±0.75% | |

| 559~610 | +2.4mm, -0.8mm | ±0.75% |

Tolerance of Wall Thickness

| Standard | Grade | Out Diameter | Wall Thickness |

|---|---|---|---|

| API 5L | A | 219.1~457 | +15%, -12.5% |

| B | 508~610 | +17.5%, -12.5% | |

| X42-X80 | 508~610 | +19.5%, -8% |

Chemical Analysis and Mechanical Properties

| Standard | Class | Grade | Chemical Analysis(%) | Mechanical Properties(min)(Mpa) | ||||

|---|---|---|---|---|---|---|---|---|

| C | Mn | P | S | Tensile Strength | Yield Strength | |||

| API 5L | PSL1 | B | 0.26 | 1.20 | 0.030 | 0.030 | 414 | 241 |

| X42 | 0.26 | 1.30 | 0.030 | 0.030 | 414 | 290 | ||

| X46 | 0.26 | 1.40 | 0.030 | 0.030 | 434 | 317 | ||

| X52 | 0.26 | 1.40 | 0.030 | 0.030 | 455 | 359 | ||

| X56 | 0.26 | 1.40 | 0.030 | 0.030 | 490 | 386 | ||

| X60 | 0.26 | 1.40 | 0.030 | 0.030 | 517 | 414 | ||

| X65 | 0.26 | 1.45 | 0.030 | 0.030 | 531 | 448 | ||

| X70 | 0.26 | 1.65 | 0.030 | 0.030 | 565 | 483 | ||

| PSL2 | B | 0.22 | 1.20 | 0.025 | 0.015 | 414 | 241 | |

| X42 | 0.22 | 1.30 | 0.025 | 0.015 | 414 | 290 | ||

| X46 | 0.22 | 1.40 | 0.025 | 0.015 | 434 | 317 | ||

| X52 | 0.22 | 1.40 | 0.025 | 0.015 | 455 | 359 | ||

| X56 | 0.22 | 1.40 | 0.025 | 0.015 | 490 | 386 | ||

| X60 | 0.22 | 1.40 | 0.025 | 0.015 | 517 | 414 | ||

| X65 | 0.22 | 1.45 | 0.025 | 0.015 | 531 | 448 | ||

| X70 | 0.22 | 1.65 | 0.025 | 0.015 | 565 | 483 | ||

| X80 | 0.22 | 1.85 | 0.025 | 0.015 | 621 | 552 | ||

Small Diameter ERW Pipe Specification

| Out diameter | Sch 5 | Sch 10 | Sch 40 | ||||

|---|---|---|---|---|---|---|---|

| Inch | mm | Thickness | Kg/mtr | Thickness | Kg/mtr | Thickness | Kg/mtr |

| 1/2" | 21.3 | 1.65 | 0.81 | 2.11 | 1.01 | 2.77 | 1.29 |

| 3/4" | 26.7 | 1.65 | 1.03 | 2.11 | 1.30 | 2.87 | 1.71 |

| 1" | 33.4 | 1.65 | 1.31 | 2.77 | 2.12 | 3.38 | 2.54 |

| 1 1/4" | 42.2 | 1.65 | 1.93 | 2.77 | 3.15 | 3.68 | 4.11 |

| 1 1/2" | 48.3 | 1.65 | 1.93 | 2.77 | 3.15 | 3.68 | 4.11 |

| 2" | 60.3 | 1.65 | 2.42 | 2.77 | 3.98 | 4.81 | 5.31 |

| 3" | 88.9 | 2.11 | 4.58 | 3.05 | 6.54 | 5.49 | 11.45 |

| 3 1/2" | 101.6 | 2.11 | 5.25 | 3.05 | 7.52 | 5.74 | 13.77 |

| 4" | 114.3 | 2.11 | 5.25 | 3.05 | 7.52 | 5.74 | 13.77 |

| 5" | 141.3 | 2.77 | 9.50 | 3.40 | 11.74 | 6.55 | 22.10 |

| 6" | 168.3 | 2.77 | 11.47 | 3.40 | 14.04 | 7.11 | 28.68 |

| 8" | 219.1 | 2.77 | 14.99 | 3.76 | 20.25 | 8.18 | 43.16 |

Large Diameter ERW Pipe Specification

| OD | WT | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | mm | 8 5/8" | 219.1mm | 10 3/4" | 273.1mm | 12 3/4" | 325.0mm | 14" | 355.6mm | 16" | 406.4mm | 18" | 457.7mm | 20" | 508.0mm | 24" | 610mm | 24 4/5" | 630.0mm |

| 0.157 | 4.0 | ---- | --- | ||||||||||||||||

| 0.197 | 5.0 | --- | --- | --- | --- | --- | --- | --- | --- | ||||||||||

| 0.236 | 6.0 | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | ||||||

| 0.276 | 7.0 | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | ||||

| 0.315 | 8.0 | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | ||

| 0.354 | 9.0 | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | ||

| 0.394 | 10.0 | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| 0.133 | 11.0 | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| 0.492 | 12.5 | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| 0.551 | 14.0 | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | ||||

| 0.630 | 16.0 | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | ||||

| 0.689 | 17.5 | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | ||||||||

| 0.748 | 19.0 | --- | --- | --- | --- | --- | --- | --- | --- | ||||||||||

Packing And Delivery

1.Packing: weaving bag, non-woven fabric, seaworthy bundle,wooden case if required.

2.Delivery: within 30 days after receiving L/C or TT.

Our Services

• Your inquiry related to our product & price will be replied within 24hours.

• Well-trained & experienced staff are to answer all your inquiries professional in English of course.

• Working time: 8:00am - 5:30pm, Monday to Friday.

• OEM is highly welcomed. We have strong R&D team here to help.

• Your business relationship with us will be confidential to any third party.

• Good after-sale service offered, please get back if you got question.

Our Services Company Information

Our company is a leading manufacturer of ERW steel pipes.

• 15 years experience, annual sales volume reaches 2.0 billion US dollars for the past five years.

• Good quality control in production process, ISO9001:2008,SGS,BV approved.

• Excellent quality and Competitive price, OEM is available.

• Available in an extensive range of stock or custom size.

• The whole process from material to finished products can be traced.

• Our factory is located in Tianjin,China.